Page 22 - Curriculum Visions Dynamic Book

P. 22

Casting using zinc alloys

Casting, pouring liquid metal into a mould

and allowing it to solidify, is a process used to make complicated shaped objects. It is

one of the oldest metallurgical techniques and is used to produce many of the bronze and brass objects described in this book.

The shapes produced by casting are also

used in many machines.

Two methods are used in casting.

In the traditional method a mould is made

to the required shape. It may be made of sand if the shape is not to be too precise,

or it may be cut from another metal or some other hard material that will not melt when the liquid metal is poured.

For most precision parts a different

system is used. The mould is first made

of metal or some other material that will stand up to high pressure. The molten

metal is then injected into the mould.

The crucial property of the metal being used for die-casting is that it should flow easily. A zinc alloy has just these properties. A die-casting alloy is typically 96% zinc,

4% aluminium and trace amounts of copper and magnesium. The addition of these other metals makes the alloy as strong as steel. The addition of copper is crucial in ensuring that the casting doesn’t warp as it sets.

The use of zinc in castings now consumes as much zinc as is used in galvanising.

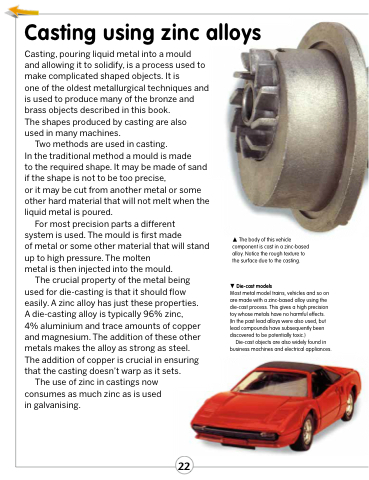

The body of this vehicle component is cast in a zinc-based alloy. Notice the rough texture to the surface due to the casting.

Die-cast models

Most metal model trains, vehicles and so on are made with a zinc-based alloy using the die-cast process. This gives a high precision toy whose metals have no harmful effects. (In the past lead alloys were also used, but lead compounds have subsequently been discovered to be potentially toxic.)

Die-cast objects are also widely found in business machines and electrical appliances.

22

22