Page 20 - Curriculum Visions Dynamic Book

P. 20

Brass and bronze

When zinc is melted, it readily combines with a number of other metals to make metal mixtures, or alloys Of these, the most important is brass, an alloy of zinc and copper with traces of other elements. In general, unless the proportion of

zinc exceeds one-third of the alloy, the greater the proportion of zinc, the stronger the brass.

Many types of brass are produced, each varying in the proportion of copper to zinc. The kinds of brass that are most easy to draw out into tubes or wires have relatively little zinc in them, perhaps one-fifth of

the total alloy. The stronger brasses, with greater zinc content, are used for keys and other parts where strength and machinability are needed, and where softness would therefore be

a major handicap. The strongest brass of all has one-third zinc along with

2% lead. It is known as leaded brass.

Bronze is an alloy of copper significantly different from brass.

Bronze is a copper alloy with tin

as its major secondary constituent.

Zinc is used to give the bronze important special properties, such as ease of casting.

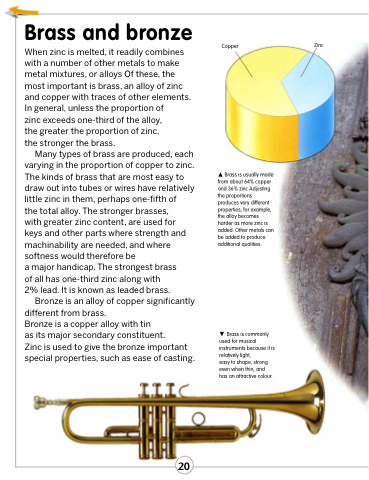

Copper

Zinc

Brass is usually made from about 64% copper and 36% zinc Adjusting the proportions produces very different properties; for example, the alloy becomes harder as more zinc is added. Other metals can be added to produce additional qualities.

Brass is commonly used for musical instruments because it is relatively light,

easy to shape, strong even when thin, and has an attractive colour.

20

20