Page 23 - Curriculum Visions Dynamic Book

P. 23

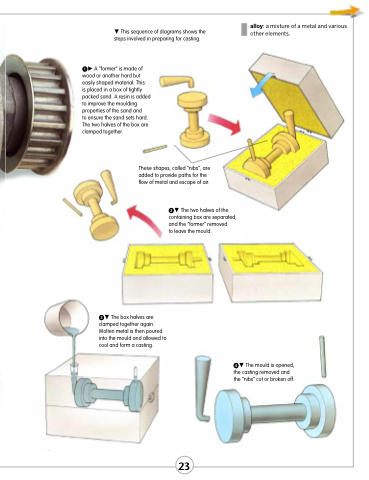

This sequence of diagrams shows the steps involved in preparing for casting.

A “former” is made of wood or another hard but easily shaped material. This

is placed in a box of tightly packed sand. A resin is added to improve the moulding properties of the sand and

to ensure the sand sets hard. The two halves of the box are clamped together.

These shapes, called “nibs”, are added to provide paths for the flow of metal and escape of air.

alloy: a mixture of a metal and various other elements.

The box halves are clamped together again. Molten metal is then poured into the mould and allowed to cool and form a casting.

The two halves of the containing box are separated, and the “former” removed

to leave the mould.

23

23

The mould is opened, the casting removed and the “nibs” cut or broken off.