Page 17 - Curriculum Visions Dynamic Book

P. 17

electroplating: depositing a thin layer of a metal onto the surface of another substance using electrolysis.

flux: a material used to make it easier for a liquid

to flow. A flux dissolves metal oxides and so prevents a metal from oxidising while being heated.

galvanising: applying a thin zinc coating to protect another metal.

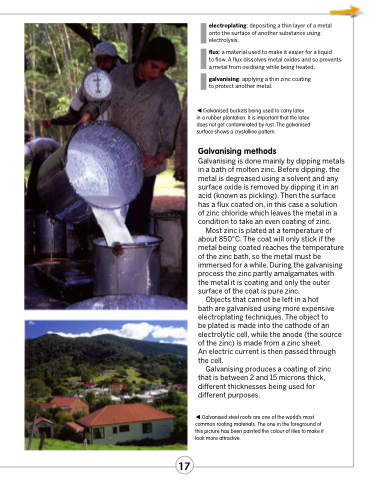

Galvanised buckets being used to carry latex

in a rubber plantation. It is important that the latex does not get contaminated by rust. The galvanised surface shows a crystalline pattern.

Galvanising methods

Galvanising is done mainly by dipping metals in a bath of molten zinc. Before dipping, the metal is degreased using a solvent and any surface oxide is removed by dipping it in an acid (known as pickling). Then the surface has a flux coated on, in this case a solution of zinc chloride which leaves the metal in a condition to take an even coating of zinc.

Most zinc is plated at a temperature of about 850°C. The coat will only stick if the metal being coated reaches the temperature of the zinc bath, so the metal must be immersed for a while. During the galvanising process the zinc partly amalgamates with the metal it is coating and only the outer surface of the coat is pure zinc.

Objects that cannot be left in a hot

bath are galvanised using more expensive electroplating techniques. The object to

be plated is made into the cathode of an electrolytic cell, while the anode (the source of the zinc) is made from a zinc sheet.

An electric current is then passed through the cell.

Galvanising produces a coating of zinc that is between 2 and 15 microns thick, different thicknesses being used for different purposes.

Galvanised steel roofs are one of the world’s most common roofing materials. The one in the foreground of this picture has been painted the colour of tiles to make it look more attractive.

17

17